Testing

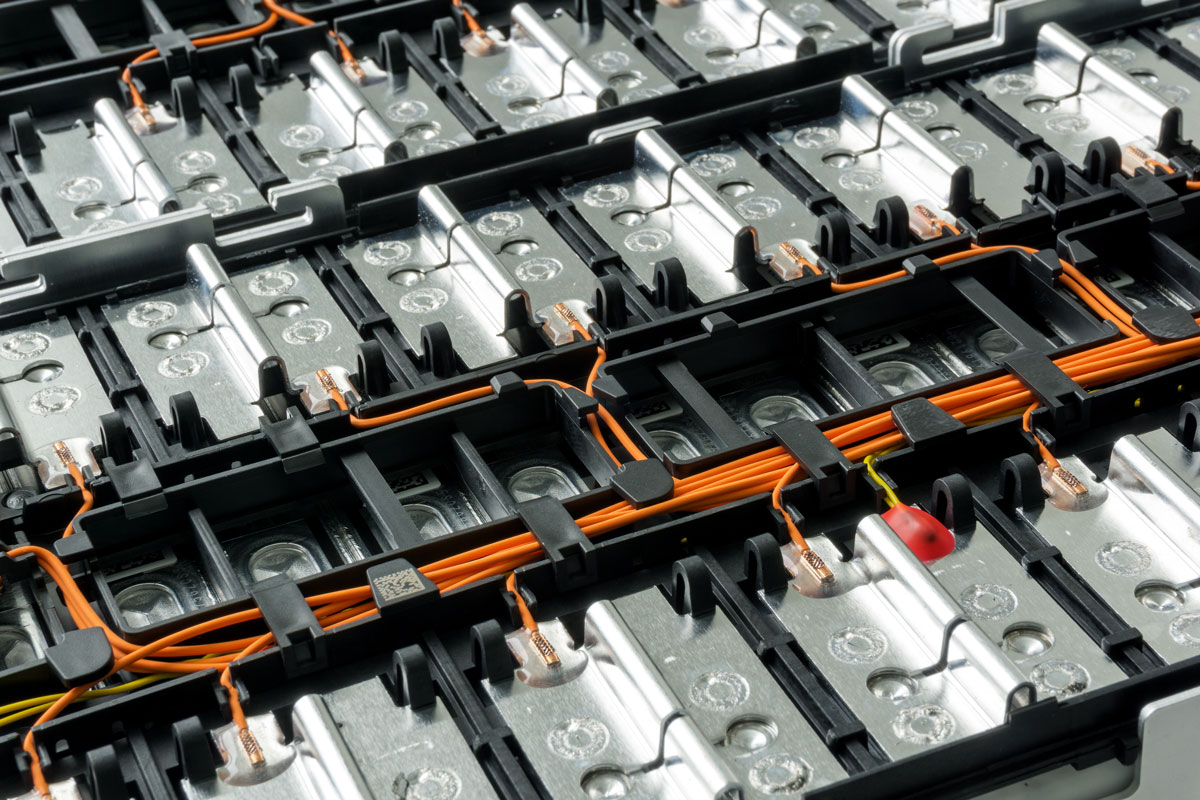

Battery:

Safety Tests

Safety is an essential component in the development of batteries and the broad acceptance of e-mobility.

To ensure that the behavior in the event of a fault and under extreme conditions can be simulated realistically and reproducibly, we offer extensive safety tests based on the current battery standards.

These primarily include electrical, thermal and mechanical interlock and misuse tests in the form of:

- Overheat

- Overload

- Mechanical damage

- Nail

- Crush

- Drop Test

- Short Circuit

- Internal

- External

Common Battery Standards:

- ECE R 100

- ECE R 136

- SAE J 2464

- IEC 62133

- UN 38.3

- LV124

- DIN EN 62620

- DIN EN 62281

- DIN EN 62660

- GB/T 31467.3-2015

Examples

Thermal Runaway & Thermal Propagation

by Nail E-BikeBatterypack 36V 19Ah

Test Object: Lithium Ion Battery Pack

Voltage: 36V

Capacity: 19Ah

SoC: 100%

Reaction Classification

According to IEC 62660: Hazard Level 6

Internal Short Circuit due to Nail

Test Object: Lithium Ion Cell

Voltage: 3.7V

Capacity: 5.000 mAh

SoC: 100%

Reaction Classification

According to IEC 62660: Hazard Level 6

Thermal Runaway & Thermal Propagation

by Nail E-Bike Batterypack 36V 19Ah

Test Object: Lithium Ion Battery Pack

Voltage: 36V

Capacity: 19Ah

SoC: 100%

Reaction Classification

According to IEC 62660: Hazard Level 6